Pretreatment

Corrosion Protection

Decorative Surfaces

Functional Layers

Disposal / Recycling

• What are the properties the workpiece must exhibit after the coating?

• Does the corrosion protection have priority? Is a decorative finish required?

• Or do purely functional properties have priority?

• Or a combination of all these requirements?

Your requirements are decisive when choosing the process!

Having a broad range of efficient, field-tested processes, Dr. HESSE GMBH & CIE KG, covers the requirements of the conventional electroplating industry.

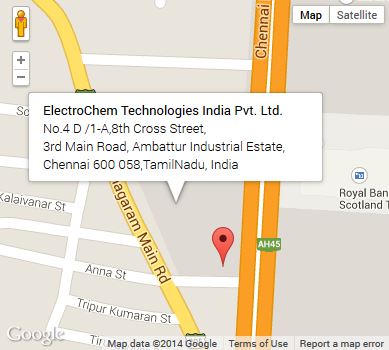

Regarding Product Corrosion Protection enquiry, please contact our Corporate Office:

|

No.4 D /1-A,8th Cross Street, 3rd Main Road, Ambattur Industrial Estate, Chennai 600 058,TamilNadu, India., Phone:

E-Mail: info@electrochemtechnologies.com Close |

|

| Zinc | Zinc alloys |

|---|---|

|

ZINKOR RGV-PG - alkaline zinc process

ZINKOR RGV-D - alkaline zinc process

ZINKOR RT matt - alkaline zinc process

LUNACID RST-ZS - acid zinc process

|

ZINKOR Ni14 B - zinc-nickel process

LUNACID Ni14 BF - boric acid-free, acid zinc-nickel process

ZINKOR FE-B - zinc-iron process

|

Passivations

HESSOPAS KS 50

- Constant blue colour

- Very long service lives

Blue passivation ZP

- When using low make-up concentrations, the corrosion protection is still very good

- Very appealing blue colour

HESSOPAS Blue passivation TS

- Stable colour also after heat treatment

- Contains an iron inhibitor

- Also with high concentrations the colour remains stable

HESSOPAS CF 200

- Cobalt-free blue passivation

HESSOPAS CF 100

- Cobalt-free thick layer passivation

- Wide working range

- Fluoride-free

- Can be combined with HESSOPAS NanoPlus

HESSOPAS CF 110

- Cobalt-free thick layer passivation

- Contains fluoride

HESSOPAS Thick layer passivation HT

- Thick layer passivation for highest corrosion protection

- Fluoride-free

- Operates at 25 °C

- Approval of automotive industry available

Thick layer passivation HESSOPAS AT

- For highest corrosion protection

- Appealing optics

- Also adjustable as blue passivation

- Wide temperature range

HESSOPAS Thick layer passivation LF & LFI

- Fluoride-free product

- Also after tempering (210 °C) highest corrosion protection

- Low make-up concentration

Inorganic

HESSOTOP EK

- Universal sealing on our passivations

- Purely inorganic system

- Good corrosion protection

Organic

HESSOTOP Z 200

- Purely organic sealing system

- Suitable for zinc surfaces as well as zinc-nickel surfaces

- Reliably prevents iridescence of passivated surfaces

Inorganic / organic hybrid

HESSOTOP Si 300 GM

- Inorganic/organic hybrid system

- Contains lubricants

- Very good corrosion protection

HESSOTOP HF 750

- Two-part system

- Particularly for black passivated surfaces

- Has a colour intensifying effect

HESSOTOP Gleitstar GH

- Very good corrosion protection

- Easy screw mounting

- Sealed for life

- Applicable for multiple screw joint

HESSOTOP HotStar

- Very good corrosion protection

- Temperature-resistant

- Does not contain any lubricants

HESSOTOP HotStar DE

- Produces defined coefficents of friction within the required range of the German Association of the Automotive Industry (µ=0.08 - 0.14)

- Temperature-resistant

- Very good corrosion protection

HESSOTOP HotStar FR

- Produces defined coefficents of friction for the French Automotive Industry requirements (µ=0.12 - 0.18)

- Temperature-resistant

- Very good corrosion protection

The HotStar series additionally contains products which reliably allow to specifically achieve also higher coefficients of friction (HESSOTOP HotStar SP 19, HESSOTOP HotStar SP25).